Not known Factual Statements About Outsourced Warehousing And Fulfillment

Wiki Article

Some Known Incorrect Statements About Outsourced Warehousing And Fulfillment

Table of ContentsUnknown Facts About Outsourced Warehousing And FulfillmentSee This Report on Outsourced Warehousing And FulfillmentOutsourced Warehousing And Fulfillment Things To Know Before You Get ThisThe 5-Second Trick For Outsourced Warehousing And FulfillmentWhat Does Outsourced Warehousing And Fulfillment Mean?The smart Trick of Outsourced Warehousing And Fulfillment That Nobody is Talking About

As more firms outsource their warehousing, they'll need to make certain they're choosing the right companion to make certain the highest degree of service. It's easier to take the following action in your endeavor since you have a firm understanding of warehousing. Having the ability to recognize the best stockroom services and relevant partnerships can spend some time; do not rush yourself.Warehousing is the process of storing as well as shipping physical products in a storage facility. Storehouses can be made use of in different organization settings for storing goods before delivering them to a particular location or various clients. As an example, a business like Walmart may use a storage facility to store its products in bulk as well as deliver them to its stores when stock fails, as well as things are required to be put on racks.

You could have discovered terms stockroom and also circulation center are utilized reciprocally. A storehouse is merely a building that is made use of to store supply.

Some Known Incorrect Statements About Outsourced Warehousing And Fulfillment

/portrait-of-three-courier-employees-inside-warehouse-sb10067610w-001-5a567142842b17003775c535.jpg)

A product that comes and also goes in and out of a storehouse goes via numerous processes. The incoming procedure is getting and saving items from a provider to a storehouse or a fulfillment.

These are as adheres to: After the trailer is docked at the storage facility, workers inspect the inventory to make certain that all items that were anticipated exist and also are not damaged. After that the inventory is assigned Permit Plate Numbers (LPNs) as well as considered putaway. After the supply is examined in the obtaining procedure, it is required to storage where it is saved.

Some discount store things together based upon the thing type or needed storage space temperature etc. to optimize storage space places to maximize place utilization. The outbound Refine is the picking, packing, as well as delivery of products from the stockroom to a client or end individual. The outgoing procedure is further split into the complying with procedures - outsourced warehousing and fulfillment.

Indicators on Outsourced Warehousing And Fulfillment You Should Know

Choosing is the procedure of collecting all the products in order from their corresponding storage places and also transferring them to a hosting location. Once all products in an order are selected and also given a staging location, the next step is to obtain them all set to be delivered to the client or end individual.

The last action in completing an order after it has been picked as well as loaded is to select an ideal service provider, tons the order on the service provider and ship it to the client's delivery address. All the above steps and also processes entailed with warehousing can easily be handled and also kept track of making use of a Warehouse Monitoring System.

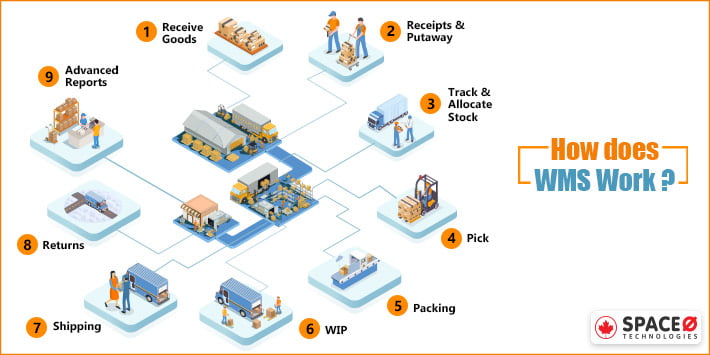

A storehouse monitoring system (WMS) includes software application and also procedures that enable companies to regulate as well as administer stockroom operations from the moment items or materials enter a storehouse till they vacate. Storage facilities rest at the facility of production and also supply chain procedures since they hold all of the product made use of or generated in those procedures, from resources to complete goods. outsourced warehousing and fulfillment.

A Biased View of Outsourced Warehousing And Fulfillment

For instance, if resources are not gotten appropriately or parts are misplaced in a warehouse, the supply chain might be slowed down or interrupted. WMSes are important in making sure that these procedures work efficiently by tracking stock as well as ensuring that items are stored and also arranged correctly, as well as delivered as well as tracked precisely.The WMS handles the data as well as procedures associating to the activity of goods with a warehouse. Figure 1 shows each system's role in processing orders and also the types of data they require to share with each various other to guarantee that the appropriate product gets to the client outsourced warehousing and fulfillment on time.

Its duty in inventory is to track the stock information that comes in from barcode visitors and also radio regularity identification (RFID) tags as well as upgrade the supply management component in the ERP system to guarantee it has the current information. An assimilation web link synchronizes the inventory data that is kept in the ERP system and also the WMS.

6 Easy Facts About Outsourced Warehousing And Fulfillment Described

It is essentially a database of in-depth information concerning delivery carriers yet is likewise a transactional and interaction system for planning, performing and also tracking the shipments. In some cases a TMS will be incorporated with the WMS to enable far better control of the inbound and also outbound logistics jobs that happen at the interface of storehouses and products shippers, such as palletization of items, labor scheduling, backyard administration, load structure and cross-docking., consisting of zone selecting, wave selecting and set selecting. Storage facility employees can likewise make use of lot zoning and job interleaving features to guide the pick-and-pack tasks in one of the most reliable way., which enables the WMS to send expenses of lading (B/L) in advance of the delivery, generate packing listings as well as billings for the delivery and send development delivery alerts to receivers.

The main quality of a cloud-based WMS versus the standard on-premises system is that the software program is organized and managed by the WMS vendor or a cloud provider. This takes the worry of installing, managing and also updating the system off the company's IT department. Due to the fact that they are less complicated to mount as well as much less costly to take care of, cloud-based WMSes tend to be favored by SMBs.

Not known Details About Outsourced Warehousing And Fulfillment

Pros of cloud-based WMS include the following: Faster execution. Standard on-premises WMSes can normally take months to carry out, whereas cloud-based WMS deployments can be completed in weeks, relying on the complexity. This means that companies have a quicker path to a favorable ROI as well as can benefit from the cloud WMS capacities quicker, which is a substantial benefit in the hectic modern economic situation.Report this wiki page